About NITTAN

NITTAN's Steps Thus Far

We will introduce NITTAN's history thus far

Where Our Products Are Used

We will introduce the main products, such as engine valves and valve parts

Product Lineup

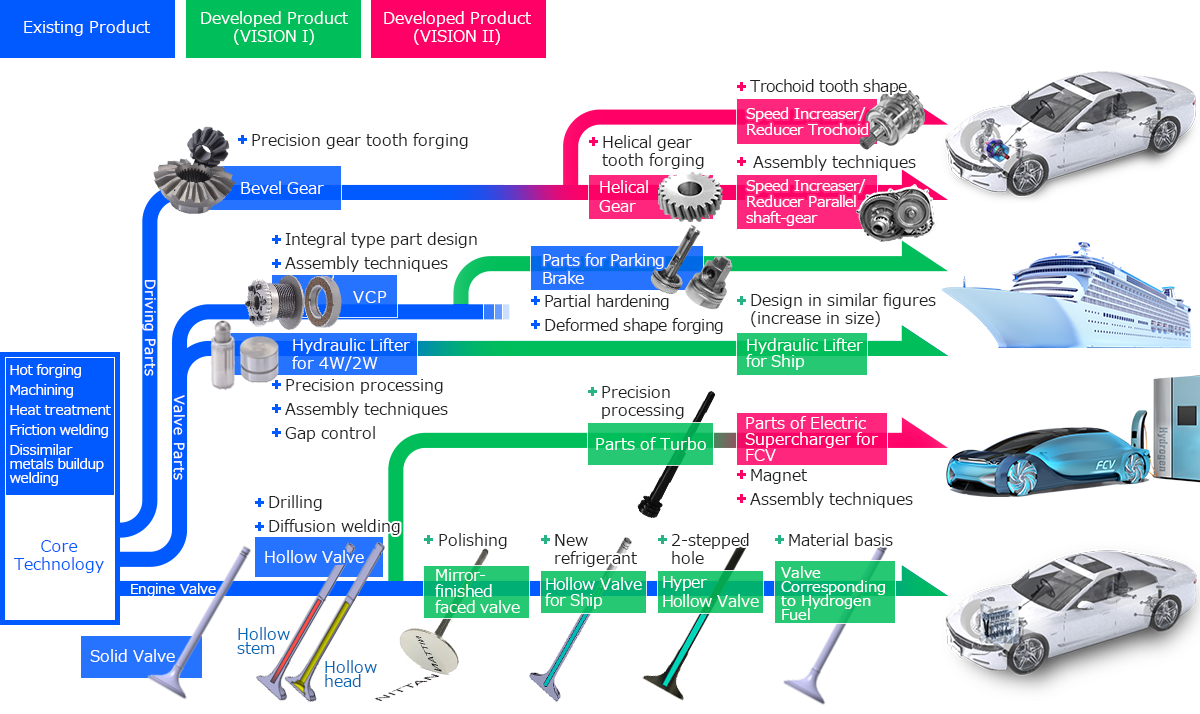

"NITTAN Challenge 10" Genealogy of Technology

We will introduce NITTAN's evolution in technology

Our core technologies are hot forging and machining which have been developed since before World War II. In addition, we possess a wide range of core technologies, such as welding by heat treatment and friction welding, dissimilar metals buildup welding by using a plasma laser, etc.

Taking advantage of know-how to produce a unit commodity (assembly) by combining the technologies such as forging and precision machining having been developed for many years, and parts, we are focusing on the development of existing products meeting hydrogen engine and fuel source diversification, as well as entry into new domains corresponding to xEV.

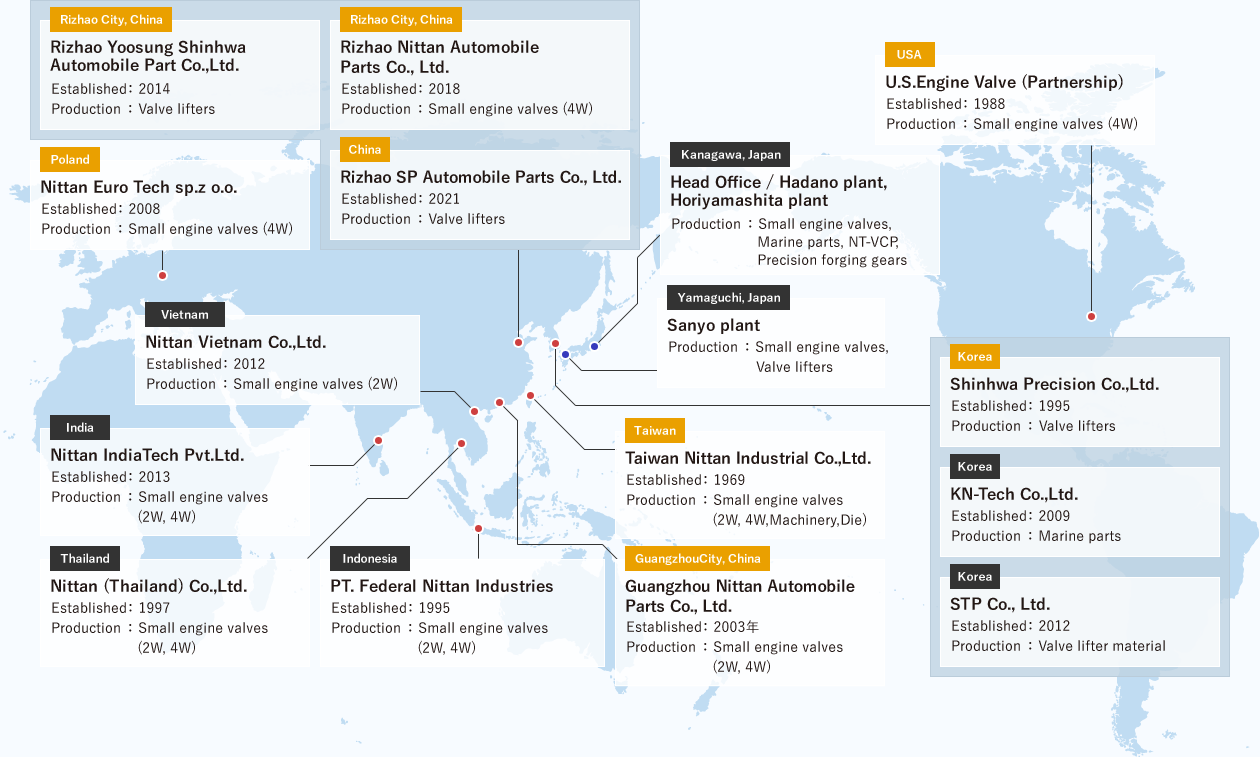

Global & Production Sites

The production system in three major regions -Asia, North America, and Europe- enables clients to optimally procure our products.

- Japanese Production Sites: 2 sites

- Overseas Production Sites: 14 sites

- Production Site through Collaboration with Eaton